MT in focus

Tiles that sing

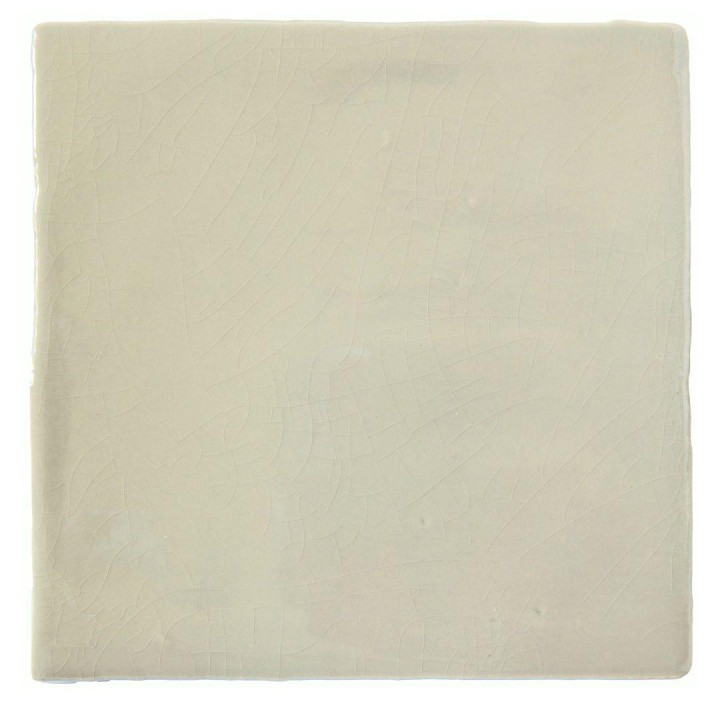

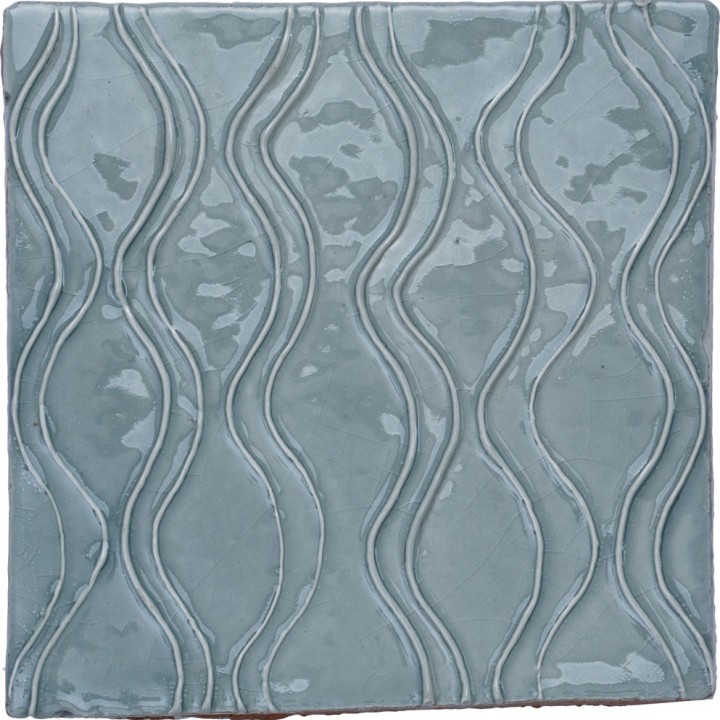

Our customers sometimes call to tell us that their new crackle glaze tiles are making little noises, even a week after they were put up on the wall. We tell them it’s just the tile singing, and explain what’s happening: the beautiful crackle glaze they chose is still crazing.

The glaze is essentially a piece of glass on top of the tile body known as the ‘biscuit’. This glaze has been carefully crafted to shatter in a controlled way as it cools. As it does so it crazes, and a network of fine cracks appears. These subtle lines are fascinating to the eye and have a remarkable delicacy, so much so that it’s hard to believe the effect is the product of a violent, semi-random physical process.

To produce a crackle glaze, one needs to get a little scientific. It is all about the coefficient of thermal expansion – the measure of how a body expands and contracts as it is heated and cooled. Normally a glaze should fit perfectly with the tile: both should expand and contract at the same rate. With a crackle glaze, however, we deliberately aim for an imperfect glaze fit. The aim is for the glaze to contract more slowly than the brick after it has been fired. But the glaze is bonded to the surface of the brick and can’t move, so as one surface contracts at a different rate from the other, the glaze comes under massive pressure.

The process can continue for a remarkably long time. Even a week after the tile has come out of the kiln, after it has been sealed and tiled onto the wall of someone’s kitchen, it can be cracking – almost imperceptibly.

Those fine cracks really are cracks, and will let in dirt. We take advantage of this to achieve our aged crackle look, using a stain that sinks into the cracks. Ultimately, though, a crackle glaze tile needs to be sealed to prevent discolouration.

To achieve a beautiful crackle glaze isn’t easy. It’s the result of a long process of research and development, and a particularly challenging one when the firing process is rapid, as ours is – 70 minutes from start to finish. When the cooling begins the temperature can drop from to 1010º to 700ºC in just five minutes, creating a massive thermal shock to the tile. It takes a lot of work to create glazes that contract only very slightly slower than the body of the brick. The differential has to be precisely right, and we have to be careful. If it’s done wrongly the glaze can simply fall off, and that can be dangerous.

But when it’s done well, the crackle glaze is a thing of remarkable beauty. Its patterns seem especially appealing because they are not planned or consciously positioned. They are the result of the laws of physics and chemistry and tiny random variations. The crackle glaze is, in fact, a thoroughly natural effect – just a very carefully controlled one.

As featured in…